Project At-a-Glance

- Shaft construction within the urban area adjacent to the waterfront and elevated highway

- Creation of 58-ft (18m) diameter opening into an unreinforced secant pile-supported shaft

- Challenging ground conditions including artesian flow

- Deepest application of unreinforced secant piles to date. Prior depth benchmark- Vargas Shaft, New Irvington water tunnel, California, was also designed by Brierley Associates

Project Narrative

“Bertha”, at 57.5-ft in diameter, was the largest EPB-TBM in the world at the time of launch in July 2013. After mining approximately 1,000-ft, Bertha encountered obstructions which resulted in the stopping of tunneling work due to mechanical problems that could not be repaired via interventions at the working face.

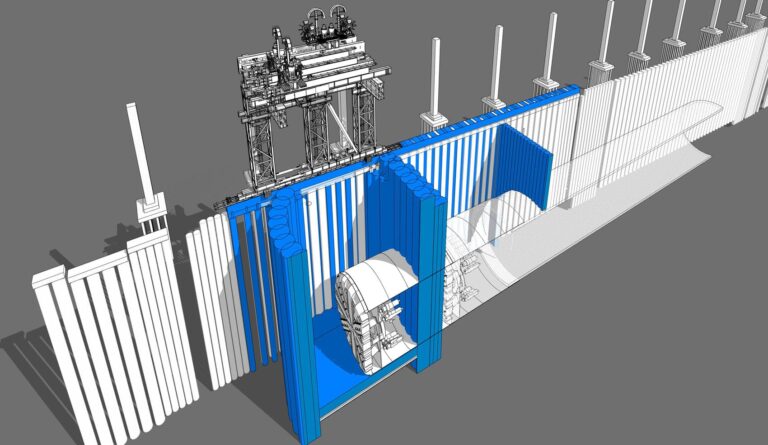

Seattle Tunnel Partners, a Joint Venture of Tutor-Perini and Dragados USA, along with the Washington State Department of Transportation determined that in order to continue, an access shaft was required to be built in front of the TBM to facilitate removal and repair of the cutter head assembly.

Brierley Associates was retained to: design an 80‑ft inside-diameter unreinforced secant pile shaft, complete finite element modeling using RISA 3D and Midas Geotechnical Tunnel System for structural and hydraulic analyses, and provide TBM cradle design, dewatering design, gantry style crane foundation analyses, instrumentation, settlement analyses, and other services.

Unanticipated subsurface conditions were encountered near the base of the shaft and beneath the secant pile tips. Instead of a hard, cohesive material, a cohesionless silt deposit was encountered during drilling for dewatering wells. As a result, an extensive dewatering and depressurization system was required to control base stability as the excavation advanced to 115-ft depth.

The access shaft was comprised of overlapping secant piles that ranged in diameter from 3- to 10-feet (1m to 3m). Settlement Mitigation Piles (SESMP’s) had been installed along each side of the TBM alignment to control tunneling-induced ground deformation. It was, therefore, necessary to interweave the shaft secant piles and the SESMP’s and grout the interstitial spaces to create a continuous wall. This resulted in an oddly-shaped shaft that, when penetrated by the TBM, caused complex bending moments to develop.

Strict settlement criteria were imposed on the gantry style crane, which was sized for a 1,300 MTON pick. The access shaft walls and pre-existing SESMP’s successfully supported the crane during TBM cutter head removal and replacement.